The Day I Almost Became a Statistic

About 18 months ago now I came as close as I ever want to be to being an industrial accident statistic. A fairly simple inspection of a small walkway almost ended up in disaster. This post shares some of my thoughts about it, in the hopes that it can help someone else avoid a similar incident.

What Happened

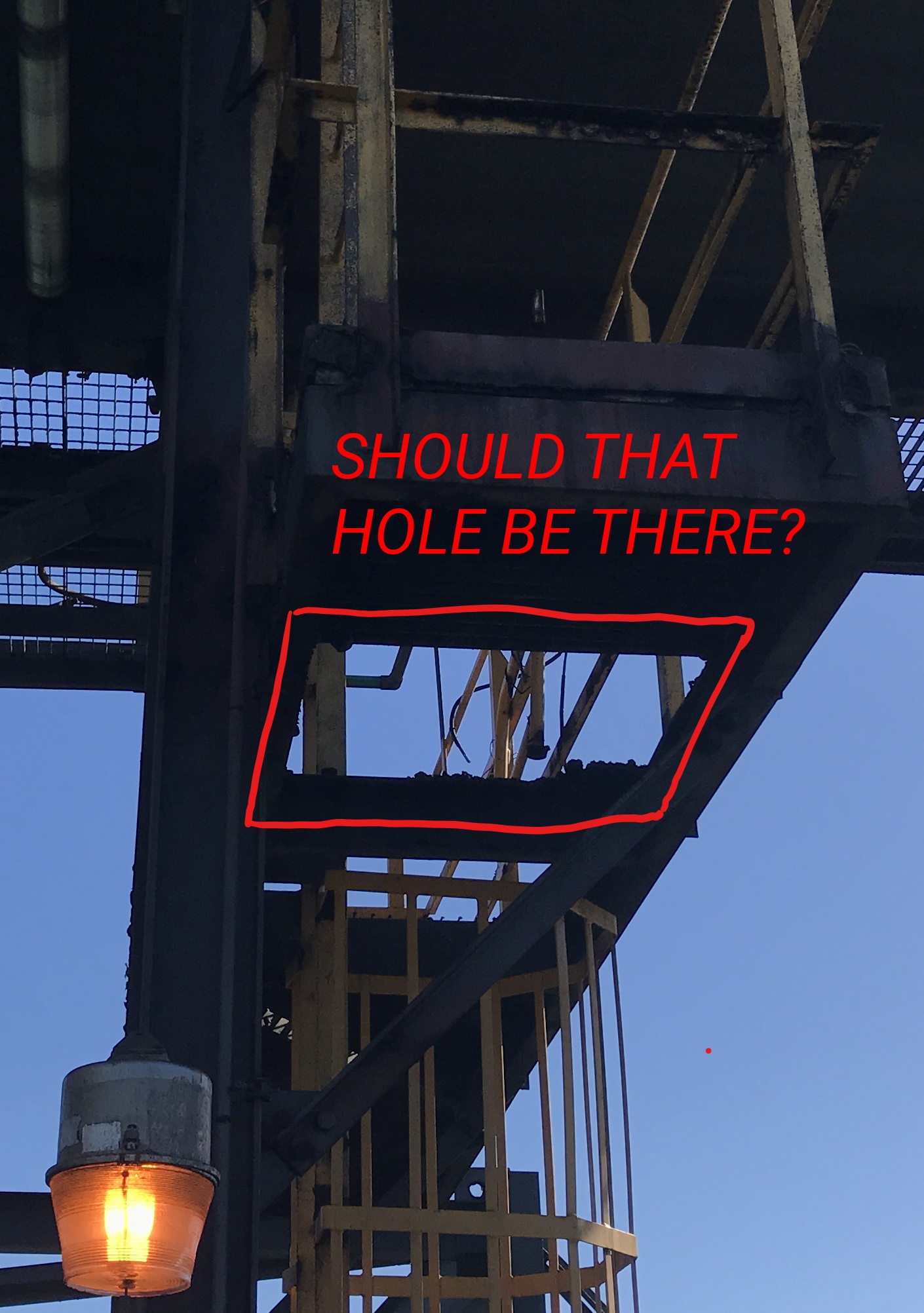

I was inspecting a conveyor structure with one of our graduate engineers, taking measurements for a repair strategy we were developing. While walking back along the conveyor towards the cribroom (we had finished for the day) we noticed that there was a heavily corroded access platform on one of the conveyor trestles. Both of us were concerned that it might be unsafe, so I decided that we needed to take a closer look at it.

At the base of the access ladder we looked up and our concerns were not eased - it looked even more corroded than from a distance. Turning to the graduate I jokingly asked him to go up and have a look for me. I can’t remember exactly what he said to me but it was clear he wasn’t going to climb the ladder and that he thought I was an idiot if I was going to.

However, after doing inspections of corroded steel for 8 years I was a little less afraid of rust than him. So I climbed the ladder to the underside of the platform for a closer look. The structure was heavily corroded but it looked like it would hold my weight. The floor mesh load bars looked like they had some surface corrosion but were approximately the right thickness, suggesting section loss wasn’t heavy. Much of what had appeared to be corrosion from below appeared to be coal stuck between the grating and dust stains on the mesh. I called out to our graduate that I was going to climb up the last few rungs onto the platform. He yelled back asking me to wait until he’d stepped out from under the platform so that I didn’t knock coal all over him. I think by now we can all see where this is going…

At the last second I thought to myself that it might be a good idea to give the platform a good kick, to see if anything happened, or at the least to clear out some of the heavy spillage that was on top of it. The first kick didn’t do anything except clear some coal through the mesh. I decided to give it a second kick to be certain, made sure I had a solid hold of the ladder stile, pulled up my leg and kick downwards - and almost fell straight through the panel of mesh.

Hanging onto the ladder with one hand and one leg trying to stop myself falling, I watched a shower of coal fall down where our graduate had been standing seconds before and saw the panel of mesh tilting on its corners through the floor trimmers. Grabbing with one hand I managed to snag the mesh before it fell. I was now hanging on for dear life, with one hand on the ladder, the other holding the mesh, one leg on the ladder and one leg dangling below the floor.

Our graduate looked up at me with a look of “what the heck do we do now” mixed with a large doses of “I told you so” on his face. After a few seconds we had both figured out that we were OK, apart from me still trying to hold onto the mesh. Luckily, about 2 minutes after the incident, someone drove up with a length of rope in his ute. We lowered the mesh to the ground, and the investigations began.

Why Did it Happen

Enough of the what though, now for the “Why”? Why did this happen, what have I learned and what can others learn from it?

Don’t Trust the Rust!

The direct cause of the incident was that the floor mesh had corroded through and I didn’t notice it. In this case as best as I could remember after the incident I remember thinking that the load bars looked like they were corroded, but that they seemed to be close to full thickness with only surface rust on most bars. Only a few had seemed heavily corroded from below. After the incident though was obvious that the majority of load bars had completely corroded through. So how did I not notice this despite having 8 years experience inspecting structures? I identified a couple of factors:

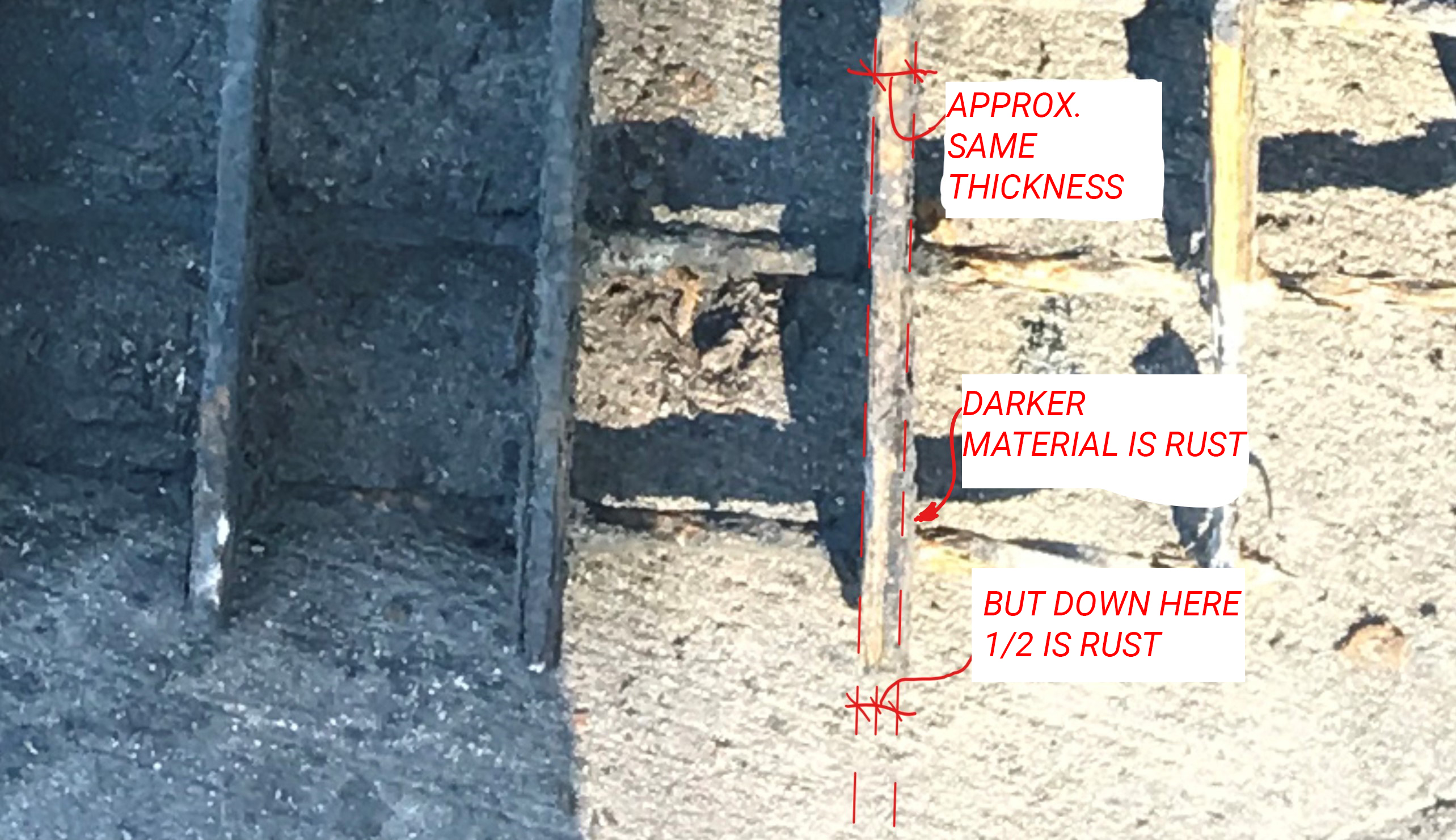

Looking at the bars, some bars looked like they were a constant thickness, but on closer inspection they had a colour variation across their thickness. The change in colour indicated that some of load bar thickness was actually rust. The following image shows a bar where 1/2 the thickness is rust (and hence has no strength). However the overall thickness was approximately the same as the original load bar thickness. With coal dust on the mesh (before it collapsed) and looking up from the ladder into the afternoon sunlight the change in colour would not have been as visible, making it hard to identify the section loss.

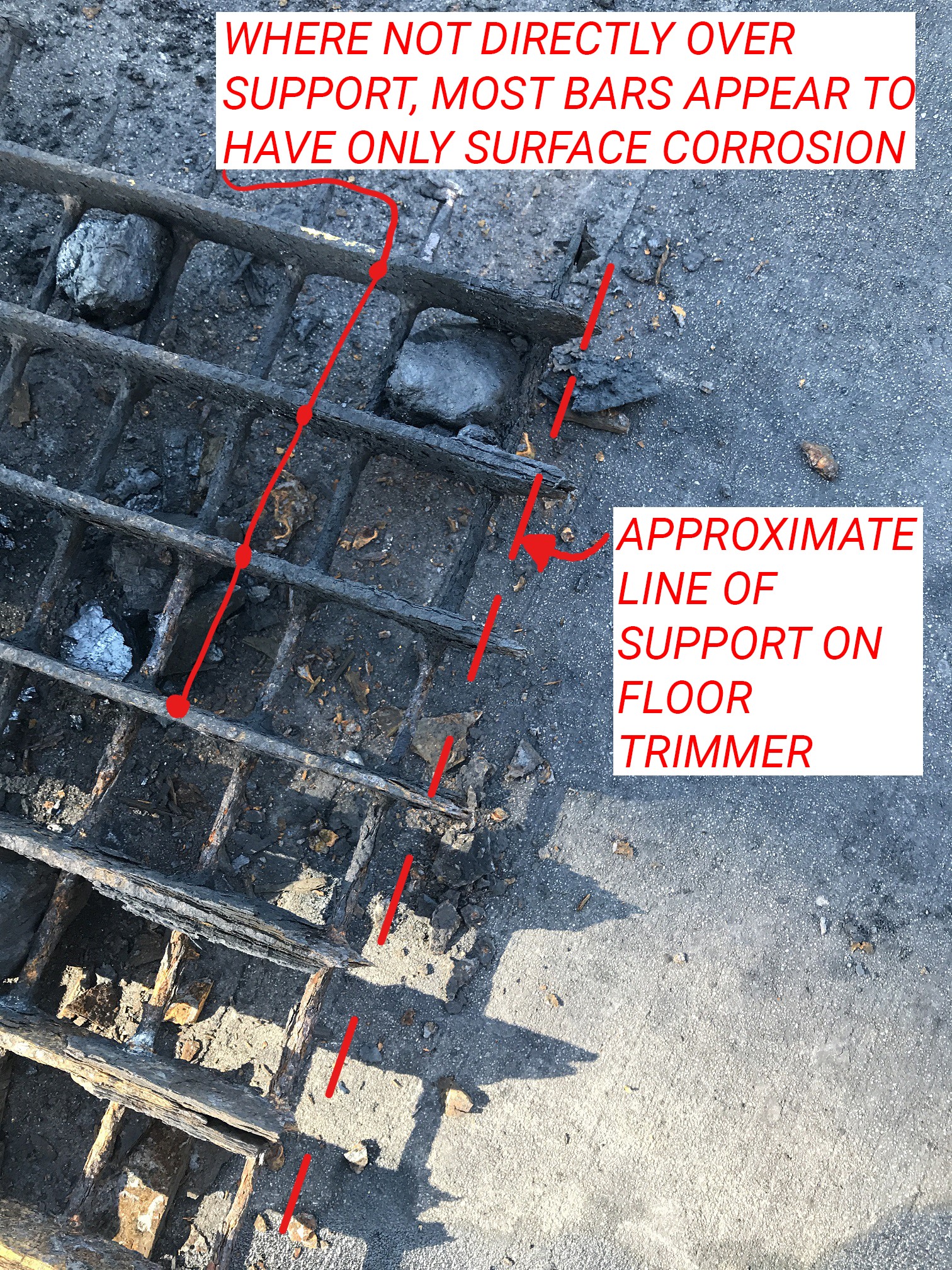

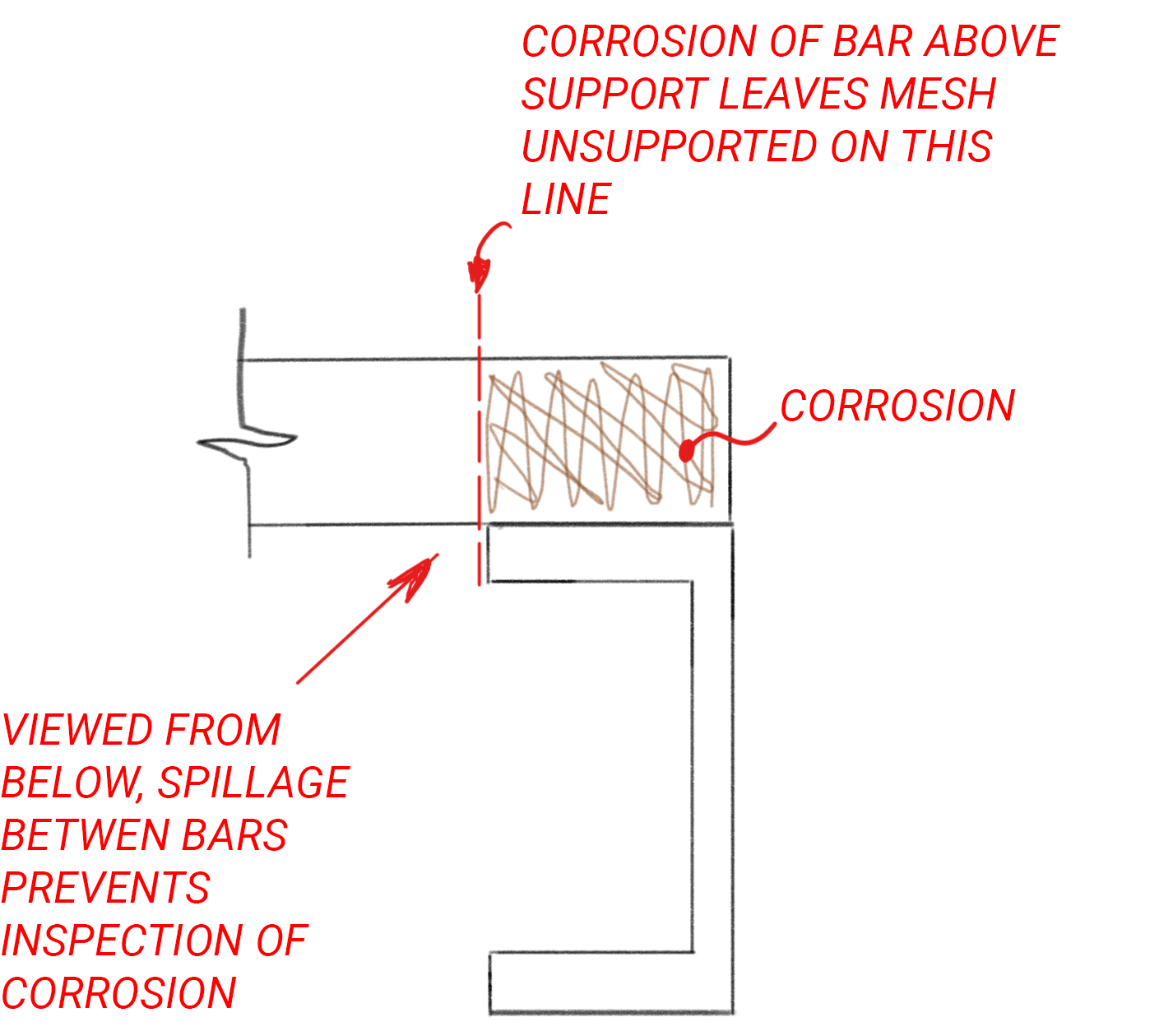

The second reason I missed the corrosion is that much of the damage appears to have occurred above the supporting floor trimmer. In this location coal buildup between the bars and the top flange of the floor trimmer would have prevented it from being visible.

The following sketch shows how this could have been difficult to see from below:

Rust is deceptive - don’t trust it! In this case I was willing to bet my life that the rust was only surface rust - and it was effectively full section loss. On other occasions I would have bet large amounts of money that section loss was extreme, yet when blasted effectively no section loss had occurred. Removal of spillage and mechanical cleaning or grit blasting should be carried out if at all possible before inspection.

Danger-Tape and Barricades Aren’t (Good) Long Term Controls

Other than corrosion, the other main factor in my near miss was the failure of barricading to prevent me accessing the platform.

About 5 minutes after I had climbed back down to ground level the graduate turned to me and said “Oh, by the way, I think I asked for that platform to be barricaded off about 12 months ago” (great timing…). Looking at the ladder in more detail we then identified that each style had a small amount of torn off danger-tape wrapped around them:

And the handrails for the walkway providing access to the base of the ladder had paint scraped off where a scaffold pole would have been placed across as a barricade:

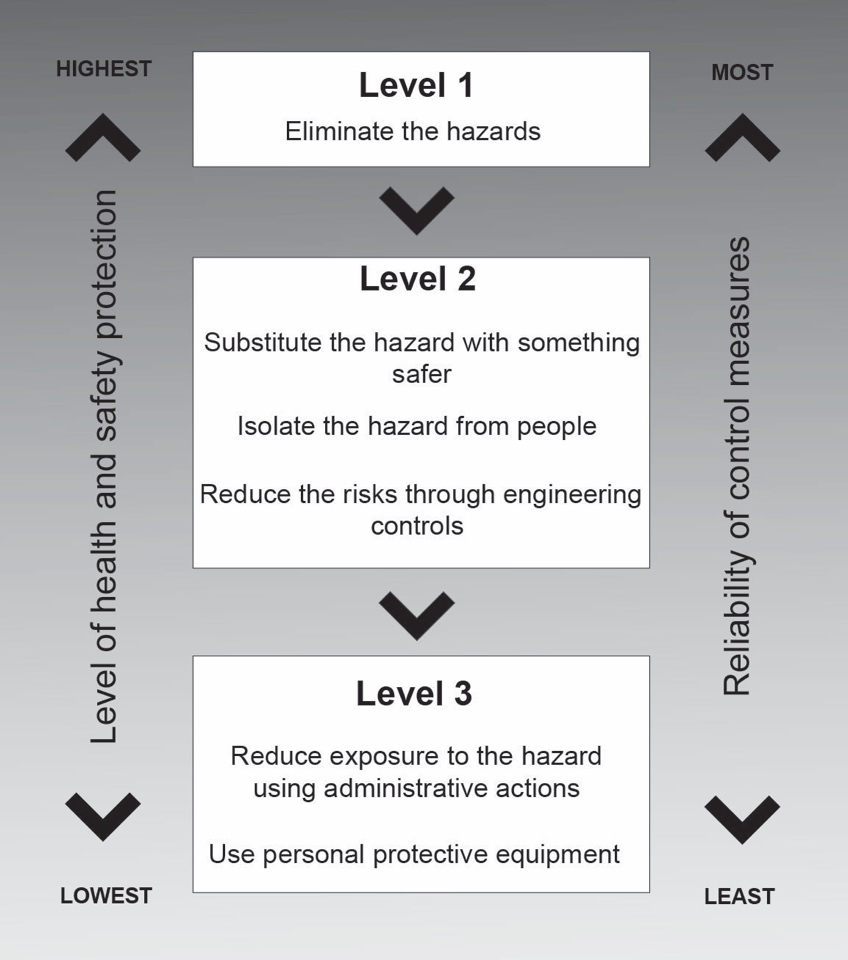

As a short term measure, the use of danger-tape and scaffold to barricade a hazard is generally a safe & reliable way of reducing risk. The following image shows the “Safety Hierarchy of Controls” (Safe Work Australia), a common means of assessing safety controls. Barricading off the ladder would have counted as isolating the hazard from people. In many cases this is likely the most effective short term control.

However, long term, is simply barricading off the structure an effective control? My near-miss shows that this may not always be the case.

What I eventually concluded is that something like the following sequence of events probably occurred:

- People forgot that the platform was barricaded off (and why).

- High winds blew the danger-tape and associated information tags off the scaffold pole & ladder.

- The site scaffolding contractor carried out one of their regular clean-ups of old scaffolding. With no danger tape and no other record of why the platform was barricaded, the scaffolders assumed the barricade was no longer required and removed it.

- The hazardous platform was now exposed for unwary engineers to access…

In the long term, danger tape is fragile and easily damaged, and scaffold is exposed to the general site hazard of being scavenged for other projects elsewhere. Systems to maintain / replace tape & barricades are administrative systems. Looking at the hierarchy of controls above, administrative controls are the 2nd weakest / least reliable form of controls.

Additionally, long term, even if the scaffold poles & danger tape prevent personnel from accessing a hazard, the hazard can become forgotten. This can then re-expose personnel to the hazard when the decision is made to rectify it.

For example, I have recently been involved in an assessment of a moth-balled facility. Large areas of the plant were barricaded off with scaffold & danger tape, and marked as unsafe. However, since it had been approximately 5 years since the plant was moth-balled, no-one knew why any of these areas were barricaded off. I was required to inspect these areas to determine what the hazards were and why areas were unsafe for access. In some areas the issues were clear. However in others I couldn’t identify any structural issues - but is this because there weren’t any issues or because I couldn’t see them? Were there mechanical / electrical hazards? How much danger did I place myself in? How much danger is still present? Who knows? It’s probably less than before I did the inspection but that’s about all I can say.

Danger tape and scaffold is probably going to continue to be used to isolate hazards - in many cases there probably aren’t any other solutions. However, this case identifies that there needs to be a robust administrative system in place to ensure that:

- Danger tape is maintained in good condition with clear and accurate info tags.

- Scaffold is regularly checked to ensure that it is in place and in good condition.

- The reason for barricading off the structure needs to be recorded. Ideally something like a site-wide register of long term barricades would be maintained, with someone responsible to ensure its accuracy, the condition of the controls and that action is being taken to remove the hazards.

Structures That Get Used Get Loved

Structures that get used get loved, and those that don’t deteriorate. The platform I almost fell from had once been used to access some electrical or mechanical items. However, these had been removed many years before. Once these were removed, there was no reason for personnel to access the platform. Un-used structures can deteriorate more rapidly for a number of reasons:

- There is no-one to carry out minor maintenance (“While I’m repairing this thing I’ll just tighten that loose bolt”), and reduced opportunities for major maintenance. Structural maintenance is often carried out at the same time as major mechanical / electrical shutdowns. If there are no electrical or mechanical components to maintain, then opportunities for structural maintenance diminish.

-

There is no production incentive to maintain the structure. While equipment is present, personnel have to be able to access it to maintain it and keep the facility producing whatever it produces. Once the equipment is gone, the condition of the redundant structure has no direct impact on production, and maintenance can be delayed without direct cost impact.

TO BE CLEAR: I am not implying that in the case of my platform that its unsafe condition was a conscious decision of anyone. I personally know many of the people who likely made the maintenance decisions about the platform, and know they would not have consciously placed anyone in danger. On the other hand, I also know the time & budget pressures that many mining & industrial facilities work under. The production incentive must at least be a factor in decision making - even if only sub-consciously.

- There is no-one to wash down spillage. In my experience it’s difficult enough to get operators to wash down walkways that they use, let alone walkways they don’t. Spillage traps moisture and contains contaminants that cause accelerated corrosion, and prevents easy inspection for damage. Section loss can be very aggressive in this environment - I have personally measured corrosion rates of >0.5mm / year. A typical floor mesh load bar is only 3mm thick and un-maintained could have a life of less than 3 years.

- There is no-one to identify the deterioration. When personnel use a structure they have an incentive to notice and report damage - their safety depends on it. Additionally, although most sites have a structural inspection regime, time & access prevent full inspection of almost every structure. Operators & maintenance personnel are extra eyes, identifying issues that inspectors do not have the time or access to see.

To address the risk of increased deterioration, redundant / unused structures should either:

- Continue to be actively maintained, with regular wash-down, maintenance and inspection.

- Be removed, either at the same time that they cease to serve a function, or at some time before they can deteriorate to an un-acceptable state.

If the choice is made to maintain a redundant structure, care needs to be taken to ensure that it really is maintained as well as any other structure on site. In particular, it may be difficult to achieve adequate wash-down and minor maintenance - will the night-shift operator get dirty and cold washing down the useless platform to nowhere that he never uses, or will he spend 15 minutes extra staying warm and cleaning his cabin windows? On the other hand, removal is elimination of the hazard - the most effective way of addressing the risk posed by deterioration of the structure.

Final Thoughts

Personally, I’m surprised at how little this incident has affected me. Until writing this post I haven’t really spent any time thinking about it. There was no time to be afraid or do anything but react when the mesh fell out underneath me. I was buzzed with adrenalin in the aftermath, but by the time I got home in the evening I had very little emotional response.

Maybe it confirms the stereotype of the cold, mathematical, un-emotional engineer. Thinking about it a little more though it’s probably just a human thing. It didn’t kill me and there were no other negative consequences so why should I spend time and energy worrying about it? We all have moments where we escape injury or death and don’t think twice. How many times have you nearly been in a car accident and thought to yourself “pheeewww that was close” and then forgotten it?

It also hasn’t put me off working in mining or heavy industry. While every near miss, injury or fatality is important, I’m about 6 times more likely to get injured on the way to or from work than on site. There were 188 Industrial Fatalities in 2017 compared to 1224 road accident deaths. This simple comparison is probably an abuse of the statistics, but it still appears likely that I face significantly more risk commuting than working (especially because I spend much of my time in the office anyway).

I’m glad that I was the one who saw the platform and chose to inspect it - I was at least worried about it. A night-shift electrician told to fix a light bulb may have simply climbed the ladder and stepped out into nothing without any warning. I’m also glad that I went up the ladder, not our graduate - it’s a cliche that you shouldn’t ask someone to do something that you’re not willing to do yourself but it’s a cliche for a reason.

Am I a more conservative engineer because of the near miss? I’m not sure. I think I’m a little less trusting of floor mesh and more willing to ask people to barricade things off. But overall though I’m not sure - I still have to think about it a bit more.

Finally, for those of you who are responsible for structures or safety on site, remember:

- Don’t trust the rust!

- Danger tape and scaffolding are useful in the short term, but as long term controls for hazards they are actually reliant on administrative (and therefore unreliable) support.

- Structures that don’t get used deteriorate - if you can, you should probably remove them rather than leave them to become a hazard.